MIL-DTL-24402F(SH)

4.6.1.1 Shock. Filter assemblies and differential pressure indicators shall be subjected to a shock test as

specified in MIL-S-901 for Grade A, Class I equipment. There shall be no evidence of damage, malfunction, or

external leakage at the conclusion of the test or during subsequent tests (see 4.6.1.2 through 4.6.1.10).

4.6.1.2 Fatigue impulse. For filter assemblies and differential pressure indicators with a fatigue pressure rating,

the fatigue pressure rating shall be verified as specified in NFPA T2.6.1. The cyclic test pressure to be used shall be

determined by multiplying the rated fatigue pressure by applicable test duration and variability factors specified in

NFPA T2.6.1 to obtain a 90 percent assurance level based on a 90 percent confidence level.

4.6.1.3 Vibration. Differential pressure indicators shall be subjected to a vibration test as specified in

MIL-STD-167-1, Type I. For this test, inlet pressure shall be between 2,700 and 3,000 lb/inē, and the outlet shall be

unpressurized. There shall be no evidence of damage, malfunction, or external leakage at the conclusion of the

vibration test or during subsequent tests. As an alternative to MIL-STD-167-1, Type I requirements, the vibration

requirements may be met by vibrating the indicators in each of the three principal directions in accordance with the

time, frequencies, and amplitudes specified in table III, followed by a 1-hour endurance test in each direction at the

highest resonant frequency noted. If no resonant frequency is noted, the endurance test shall be conducted at

50 hertz.

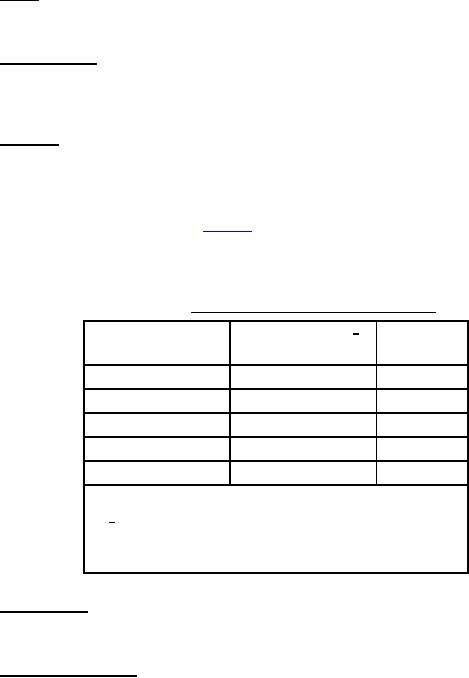

TABLE III. Vibratory displacement single amplitude.

Table amplitude 1/

Frequency range

Time

(inch, minimum)

(Hz)

(minutes)

4 to 15

0.05

2

16 to 25

0.04

1

26 to 33

0.03

1

36 to 40

0.02

1

41 to 50

0.01

1

NOTE:

1/

For Government-conducted tests, the maximum

amplitude shall not exceed the minimum required

amplitude by more than 20 percent.

4.6.1.4 Proof pressure. A proof pressure, as specified in 3.6.3, shall be applied to the filter housing and

differential pressure indicators and held for 2 minutes. For qualification, this test shall be performed after the

completion of shock and fatigue impulse tests.

4.6.1.5 Housing pressure drop. This test shall be conducted with a dummy element installed as specified in

3.5.4. Using the test fluid, the maximum pressure drop between the inlet and outlet of the filter housing at rated

flow shall not exceed the value specified in the applicable specification sheet. Rated flow for each filter housing

shall be as specified in the applicable specification sheet.

9

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business