MIL-DTL-24402F(SH)

4.2.2.1.3 Assemblies with different indicators. Qualification approval for an assembly with a different form of

differential pressure indicator may be extended from the original assembly qualification provided the additional

form of differential pressure indicator has passed qualification tests.

4.2.2.1.4 Assembly consisting of qualified components. Qualification approval without additional testing will

be considered for an assembly that is formed by combining previously qualified components.

4.2.2.2 Differential pressure indicators. Fatigue impulse tests may be extended from qualified assemblies for

which the only differences are the actuation pressure and operating pressure range.

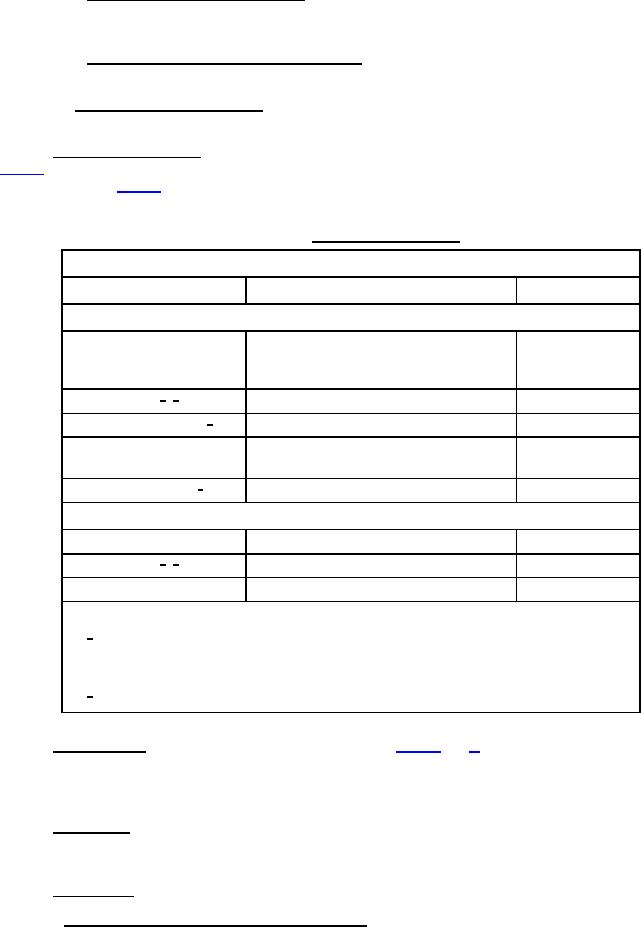

4.3 Conformance inspection. Conformance inspection shall consist of the examinations and tests specified in

table II. Conformance inspection shall be conducted on each filter housing and differential pressure indicator in the

sequence shown in table II. Any filter housing or differential pressure indicator containing a defect shall be rejected.

TABLE II. Conformance inspection.

Individual inspection

Examination and tests

Requirement

Test method

Filter housings

Examination

Proof pressure 1/, 2/

Relief valve operation 1/

Selector valve operation

and leakage

Check valve leakage 1/

Differential pressure indicators

Examination

Proof pressure 1/, 2/

Operation

NOTES:

1/

Fluid temperature and viscosity specified in 4.4 do not apply. When test fluid other

than MIL-PRF-17331 is used for leakage tests, increased leakage rates are only

permitted when specifically approved by the qualifying activity.

2/

Proof pressure test shall be conducted prior to all other tests.

4.4 Test conditions. Unless otherwise specified (see 6.2 and tables I and II), the hydraulic fluid used for all

tests shall conform to MIL-PRF-17331. Where MIL-PRF-17331 fluid is used for testing, the fluid temperature shall

be that temperature at which the actual fluid viscosity is 100 centistokes, and the temperature shall be maintained to

±1.8 °F (1 °C).

4.5 Examination. The filter housings and differential pressure indicators shall be examined to determine

compliance with the requirements specified herein with respect to design, visible defects, dimensions, marking, and

workmanship.

4.6 Test methods.

4.6.1 Filter housings and differential pressure indicators. Unless otherwise specified herein, all tests shall be

conducted with filter elements installed.

8

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business