MIL-DTL-24402F(SH)

6.5 Assembly drawings. The requirement for assembly drawings should be considered when this specification

is applied on a contract (see 6.2). If assembly drawings are required, two sets of assembly drawings, in accordance

with ASME Y14.100, should be furnished with each new model filter assembly submitted for qualification tests.

Assembly drawings should show a cutaway section of details in their normal assembly positions and should carry

part numbers of details and subassemblies. The following data should be furnished on, or together with, the

assembly drawings:

a.

Outline dimensions of the complete assembly.

b.

Dimensional location of ports, port sizes, and port identification markings.

c.

Dimensional location and size of mounting holes.

d.

Cross-sectional views showing internal flow paths.

e. Bill of material, listing specifications, grade, and condition, or other data needed to identify the materials

proposed.

f.

Complete dismantling procedure and description of tools needed.

g.

Any special installation or operating instruction considered necessary.

6.6 Indicators for logistic support. When the differential pressure indicators are procured as separate items

(see 6.2), an instruction sheet should be packed with each indicator and should contain, at a minimum, the following

statement: "Installation information. For mounting fastener material and torque requirements, see applicable filter

assembly drawing or S9086-S4-STM-010, Naval Ships Technical Manual Chapter 556 Hydraulic Equipment

(Power Transmission and Control), Section titled "Filtration". The length of the fastener for mounting this indicator

is (indicate length which will provide an engagement between 1¼ and 1½ times the diameter of the fastener)."

6.7 Cushioning and wrapping materials. Materials that have properties for resistance to fire and are acceptable

for use within unit packs and shipping containers for Navy acquisitions are:

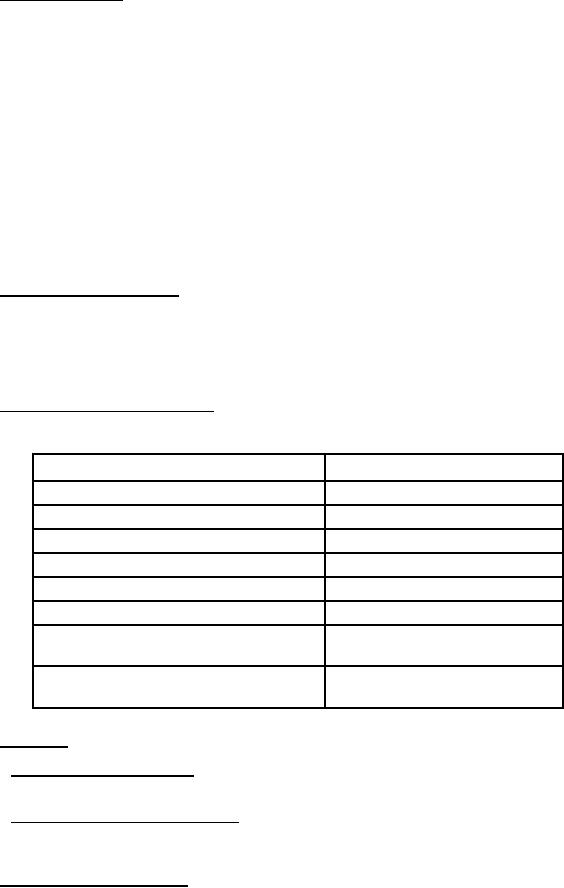

Material

Specification

Plastic film, flexible, cellular

PPP-C-795, Class 3 - fire-retardant

Bound fiber

PPP-C-1120, Type III or IV, Class C

Fibrous glass

MIL-C-17435

Polystyrene foam

MIL-P-19644, Type II

Rubber, cellular synthetic

MIL-PRF-20092, Class 5

Polyurethane foam

MIL-PRF-26514

Foam-in-place packaging materials; general

MIL-PRF-83671

specification for

Foam, combustion retardant, for cushioning

MIL-F-87090

supply items aboard navy ships

6.8 Definitions.

6.8.1 Relief valve cracking pressure. Relief valve cracking pressure is the pressure at which the relief valve

internal leakage exceeds the minimum value identified on the applicable specification sheet for internal leakage.

6.8.2 Relief valve minimum reseat pressure. Relief valve minimum reseat pressure is the pressure at which the

relief valve internal leakage drops below the minimum value identified on the applicable specification sheet for

internal leakage.

6.9 Subject term (key word) listing.

Filter housing

Hydraulic component

13

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business