WV-F-2849

1/2 gpm per square foot (0.032 L/s per square meter) of filter bed area. Filter

capacity for type III units shall be based on a flow of feedwater of not greater

than 1 gpm per square foot (0.063 L/s per square meter) of effective filter

q edia area.

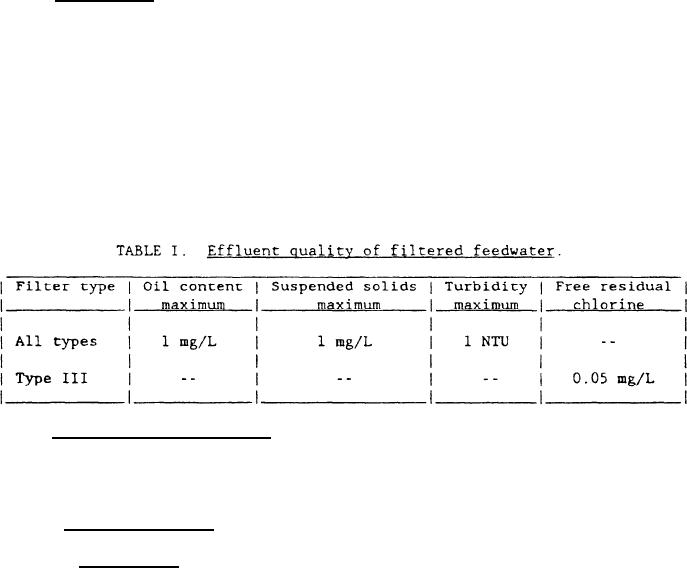

3.8 Performance. When operating at the conditions specified in 3.6, the

feedwater effluent quality from the filter system shall not exceed the maximum

concentration indicated in table I. The oil content and suspended solids and

free residual chlorine content of the boiler feedwater shall be expressed in

milligrams per liter (mg/L). The turbidity shall be expressed in nephelometric

turbidity units (NTU) as defined in ASTM D1889. Nephelometric turbidity

measuring methods shall be used for feedwater with less than 40 NTU. When

operating with feedwater impurity levels specified (see 3,6.3), the cleaning

operation shall be not more than once every 24 hours for type I and type II

units . The filter bed for type II units shall require replacement not more than

once every 6 months. The disk-cartridge for type III units shall require

replacement not more than once every 3 months. The operating hours shall be

based on the filter unit not exceeding a 15 psi (100 kPa) pressure differential.

3.9 Dimensional requirements. The layout of the equipment shall be in such

manner that all components shall be located within the boundaries of the plot

dimension (length x width), as specified (see 6.2), with provisions for adequate

room for installation, operation, and maintenance of each individual component.

3.10 Type I components.

3.10.1 Filter tank. The filter tank shall be welded carbon steel, equipped

with supports for the filter leaves or elements. Division members between

compartments shall be tightly attached to the shell so that no fluid can be

bypassed. The tank shall have a feedwater inlet, feedwater discharge, sludge

drain, vent, pressure relief device, and gage connections. The filter inlet

shall be so baffled that the filter layers shall not be disturbed by incoming

The interior arrangement of the tank shall permit cleaning

feedwater,

operations and removal of interior components with ease. The tank shall be

equipped with a quick opening and closing head. A support designed so that the

head may be withdrawn or swung out of the way for leaf removal shall be

provided. A support or fixture shall be provided to facilitate handling the

leaves when they are removed and returned to the tank. The design and

construction of the filter tank shall conform to ASME Boiler and Pressure Vessel

Code, Section VIII, Division 1, and shall be furnished with the ASME Code stamp.

The filter tank shall be securely mounted on support legs or cradles. When

specified (see 6.2), the -tank shall be -equipped with a filter element so that

the used precoat can be separated from the flushing water when the flushing

water is discharged to the floor drain.

6

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business