MIL-PRF-52666F

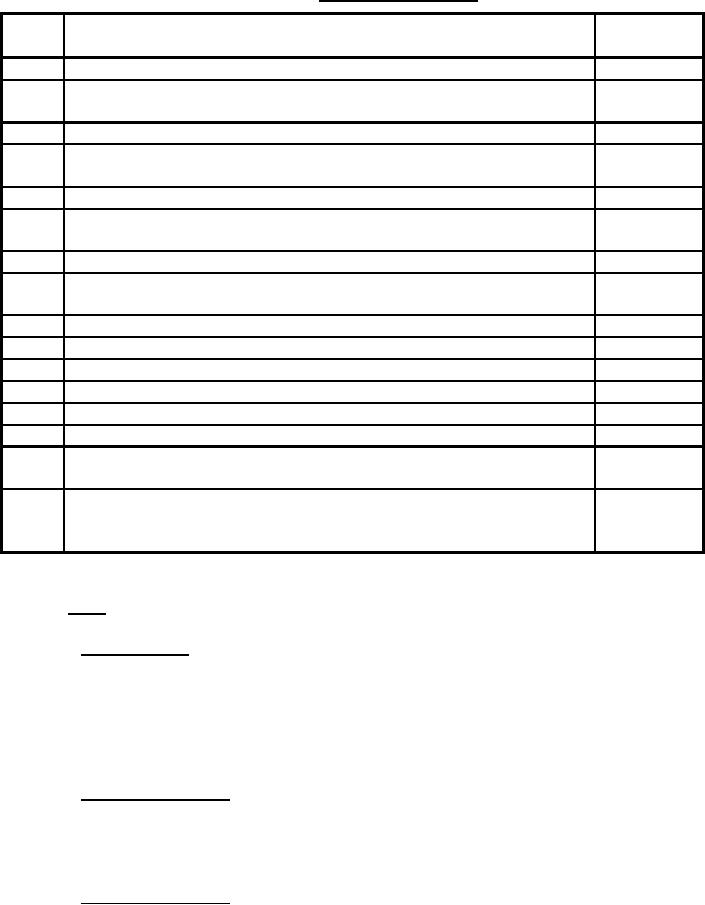

TABLE III. Examination schedule.

EXAM

EXAMINATION DESCRIPTION

METHOD

NO.

101

Materials not as specified (see 3.2).

Visual, Doc

102

Material not resistant to corrosion and deterioration or treated to be

Visual, Doc

made resistant to corrosion and deterioration (see 3.2.1).

103

Dissimilar metals (see 3.2.2).

Visual, Doc

104

The F/S does not interface with the filter-coalescer element(s) or

Visual

separator stages specified (see 3.5.1 and 3.5.2).

105

F/S inlet and outlet fittings are not as specified (see 3.5.3).

Visual

106

The F/S does not present low silhouettes or low centers of gravity as

Visual, SIE

specified, dimensions and/or weight limits exceeded (see 3.5.4).

107

Differential pressure dial gauge not as specified (see 3.3.7).

Visual

108

Adapter and sampling probe unsatisfactory or not as specified

Visual, SIE

(see 3.3.8).

109

Water drain valve not as specified (see 3.3.9.1).

Visual

110

Water level sight gauge not as specified (see 3.3.9.2).

Visual

111

Air relief valve not as specified (see 3.3.9.3).

Visual, SIE

112

F/S not painted with chemical agent resistant coating (see 3.6).

Visual, Doc

113

Color of F/S not as specified (see 3.6).

Visual

114

Labeling incorrect, illegible, or missing (see 3.7).

Visual

115

Filter-coalescers and separator stages are missing or not as specified

Visual

(see 3.8).

116

Components and parts of any one F/S not interchangeable with like

Visual

components or parts from any other F/S of the same type and class

(see 3.9).

SIE = Standard Inspection Equipment

Doc = Documentation

4.5.2 Tests.

4.5.2.1 Water removal. This testing shall follow the differential pressure tests (see 4.5.2.3).

At 15 minute intervals, the fuel flow shall be stopped by closing a quick-closing valve located

downstream from the effluent sampling connection. The fuel flow shall be immediately

reestablished and the test continued after each stop. The water shall be injected at a rate of 5 %

by volume at 115 % of rated flow for 60 minutes. Nonconformance to 3.3.2 and 3.3.3 shall

constitute failure of this test.

4.5.2.2 Hydrostatic pressure. Each F/S shall be subjected to a hydrostatic pressure test as

specified in 3.3.5. The air relief valve shall be closed during this test. Evidence of leakage,

permanent deformation, or other defects that harmfully affect the performance and serviceability

of the F/S, shall constitute failure of this test.

4.5.2.3 Differential pressure. Differential pressure across the test F/S shall be measured prior

to the start of the water removal test specified in 4.5.2.1. Nonconformance to 3.3.6 shall

constitute failure of this test.

9

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business