MIL-PRF-15618H (SH)

3.5 Physical requirements.

3.5.1 Size and weight. The size and weight of the filter-separator assembly shall meet the specified flow

capacity (see 3.4.1) and all other requirements of this specification.

3.5.2 Air eliminator. When specified (see 6.2), an air eliminator meeting the requirements of API/IP 1581 shall

be provided. The air eliminator shall be removable for maintenance.

3.5.3 Water-slug shutoff. The filter-separator assembly shall be provided with a means of automatically

stopping fuel discharge from the vessel when water in the sump exceeds the capacity of the drain system. The

device shall automatically revert to normal operation of the filter-separator during release of and after water is

drained. The water-slug shutoff shall be designed to secure filter-separator effluent upon failure of the automatic

device. A means of periodically testing the water-slug shutoff feature (without adding water) shall be provided.

3.5.4 Manual sump drain. A manually operated drain shall be installed at the low point of the filter-separator

sump. The sump shall be fitted with an anti-vortex device to inhibit discharge of fuel with the water.

3.5.5 Automatic sump drain (optional). When specified (see 6.2), an automatic drain shall be installed in the

sump drain line to automatically drain water during normal filter-separator operation. The automatic sump drain

shall be designed to secure drain line flow upon failure of the automatic device. A means of isolation shall be

provided upstream of the automatic drain device to permit maintenance. A visual flow indicator shall be provided

downstream of the automatic drain device and shall be removable for maintenance.

3.5.6 Sampling connections. Sample connections shall be provided at the filter-separator inlet, outlet, and

sump to permit taking of fuel samples under flow conditions.

3.5.7 Level indication. A level indicating device shall be provided for observing water accumulation in the

sump. The range of indication shall extend as close as possible to or below the bottom of the sump and shall provide

indication of the cleavage line between the fuel and water. A means of isolation and draining shall be provided.

3.5.8 Pressure indication. Pressure indicating devices shall be provided for observing the filter-separator inlet

and outlet pressures. A differential pressure gage shall be installed with an audible alarm to alert operator when

pressure has reached prescribed limits across each stage of filtration, and display the pressure drop across each stage.

A means of isolation shall be provided for maintenance of gages.

3.5.9 Accessibility and location. All components requiring manual operation or periodic maintenance shall be

easily accessible. Indicators shall be located within view of components requiring operation.

3.5.10 Fabrication. The filter-separator assembly shall be fabricated in accordance with the ASME Boiler and

Pressure Vessel Code, Section VIII, Pressure Vessels. Pipe thread connections shall not be used. Silver braze and

solder joints shall not be used. Permanent joints shall be welded. Mechanical joints required for disassembly shall

be flanged (2-inch NPS and larger) or union (below 2-inch NPS).

3.6 Interface requirements.

3.6.1 Inlet and outlet connections. Filter-separator assemblies shall have horizontal, flanged inlet and outlet

connections in accordance with ASME B16.5. Inlet and outlet connections shall be permanently marked. End

connection size and type, shall be specified by the purchaser (see 6.2k).

3.6.2 Fuel types. The filter-separator assembly shall meet the requirements of this specification when operated

with the following fuels:

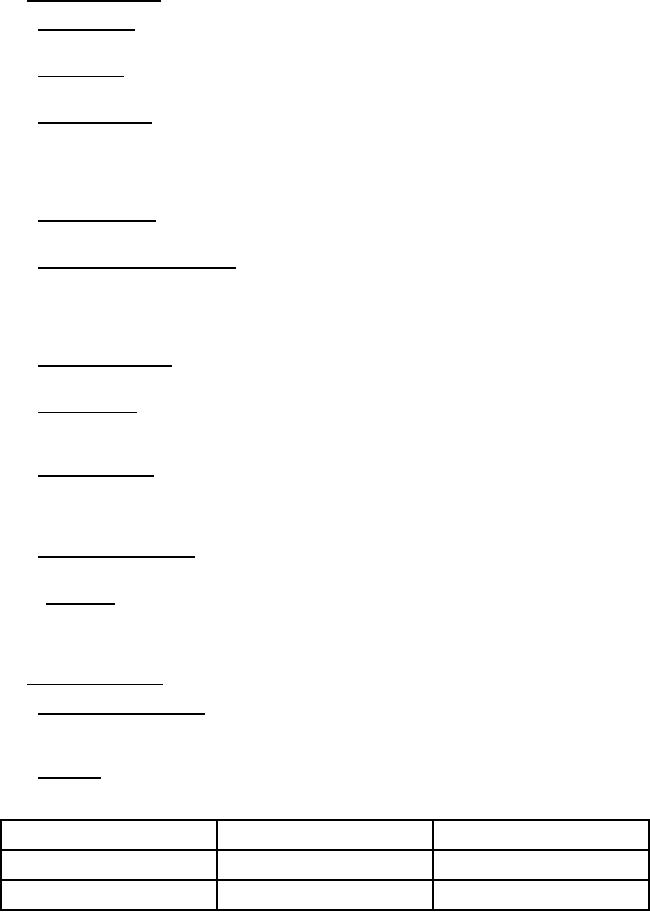

Type

NATO code no.

Specification

JP-5

F-44

MIL-DTL-5624

Naval distillate

F-76

MIL-PRF-16884

3

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business