MIL-F-52429F

103.

Dissimilar metals as defined in MIL-STD-889 are not effectively

insulated from each other (see 3.3.1.1).

Used, rebuilt, or remanufactured components pieces, or parts

104.

incorporated in the filter-separator (see 3.3.2).

105.

Differential pressure dial gauge not as specified (see 3.6).

106.

Hardware such as bolts, nuts, washers, and screw threads not as

specified (see 3.8).

107.

Cover gasket replacement not as specified (see 3.9).

Sight gauge gasket replacement not as specified (see 3.10).

108.

Chemical coating not as specified (see 3.12.1).

109.

Filter-separators not cleaned and air dried after testing (see 3.13).

110.

Workmanship not as specified (see 3.14).

111.

Weldments and castings not as specified (see 3.14.1).

112.

Welder certification not available as specified (see 3.14.1.1).

113.

Dimensions not as specified.

114.

Identification marking incorrect, illegible, or missing (see 3.11).

115.

Instruction plates are not as specified (see 3.11).

116.

Treatment and painting not as specified (see 3.12).

117.

Color not as specified (see 3.12).

118.

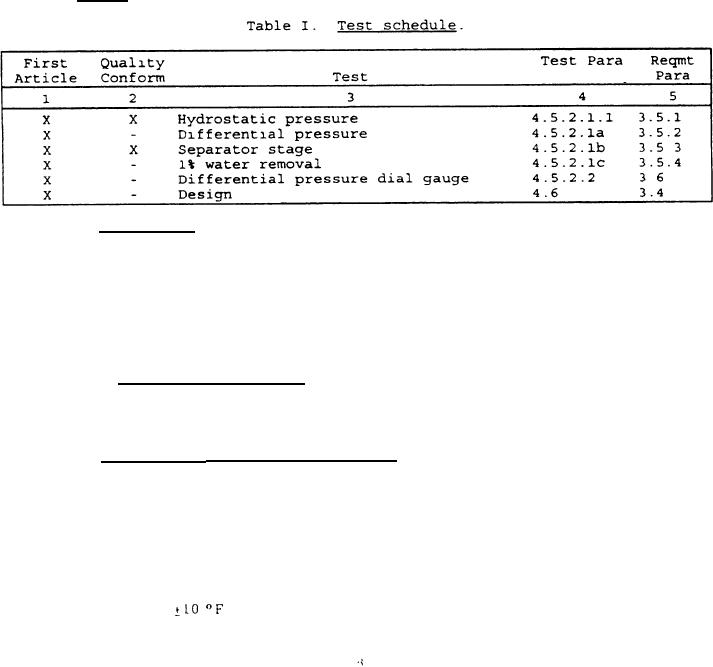

Tests.

4.5.2

The filter-separators shall be tested to the

4.5.2.1 Performance.

following performance requirements as specified in MIL-F-8901, table III.

a.

Differential pressure.

Permanent separator stage (inside to outside design).

b.

Water removal, one percent.

c.

Nonconformance to any requirements of 3.5.2 through 3.5.4 or to the applicable

requirements of MIL-F-8901 shall constitute failure of this test.

4.5.2.1.1 Hydrostatic pressure.

The hydrostatic pressure test shall

conform to the requirements specified in 3.5.1 and 3.5.1 1 of this

Nonconformance to 3.5.1 and 3.5.1.1 shall constitute failure

specification.

of this test.

Subject the gauge to a

4.5.2.2 Differential pressure dial gauge.

hydrostatic pressure equal to the maximum scale pressure, and hold at this

Within 10 minutes after the pressure is

pressure for a minimum of 30 minutes

released and without recalibration or adjustment, readings shall be taken at

the anticipated initial operating pressure, the

three intervals on the scale

pressure at which the elements are to be changed, and the maximum scale

The gauge shall be tapped sharply with the finger at approximately

pressure

A dead-weight tester or

the center of the scale area before each reading.

mercury manometer with air pressure or calibrated check gauge shall be used in

Testing of the gauge shall be in an ambient

calibrating the gauge.

Nonconformance to 3.6 shall constitute failure of

temperature of 68

this test.

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business