MI L- F-24666 (SH)

required by 4.7.4.7 and may be adjusted by varying the level of the oil in the

reservoir.

A turbulent method in accordance with ANSI B93.19 shall be provided

for transferring fluid from the contaminant injection circuit to the element test

Samples for analysis shall

0.025 L/min

circuit to yield a flow rate of 0.5

be taken from the point of injection.

Sample analysis methods. Automatic particle counters shall be

4.7.4.5

used to determine the number and size distribution of particles in the fluid

samples taken from the element circuit. The particle counters shall be

calibrated in accordance with ANSI B93.18 for 3 and 5 micrometer sizes.

4.7.4.6 Test contaminant. The contaminant shall be standardized ACFTD

and shall be obtained from Naval Air Development Center (NADC), Warminster,

PA 18974. The amount of test dust (W) shall be at least 1.2 times the element

apparent capacity In milligrams (mg) to assure a sufficient amount of contaminant

for the test.

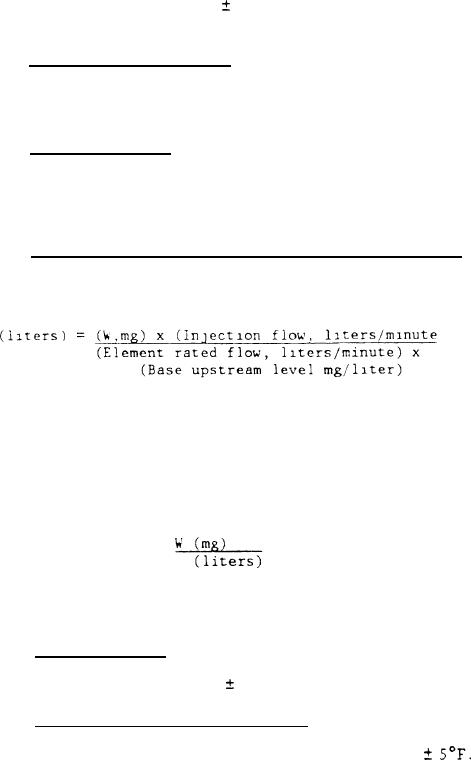

4.7.4.7 Fluid volume of the contaminant injection circuit. The fluid

volume of the contaminant injection circuit is related to the amount of

contaminant required to load the element and the element rated flow and shall

be determined as follows.

Where:

= Contaminant injection fluid volume, liters

W = Amount of test dust, mg (minimum) (see 4.7.4.6)

Injection flow = 0.5 liters/minute

10 mg/llter

Base upstream level:

Based on these values, the gravimetric level of the contaminant

injection circuit is:

Injection fluid volume may be increased as desired by increasing

Note:

the amount of test dust.

4.7.4.8 Test conditions.

(a) The test fluid (element test circuit and

(b) The

contaminant injection circuit) shall be oil conforming to MIL-H-5606.

test fluid temperature shall be 100

5°F throughout the test.

4.7.4.9 Element test circuit validation. Adjust the volume of fluid in

Install a filter

the element test circuit to the required volume (see 4.7.4.3).

Contaminate

housing or conduit. Adjust test fluid temperature to 100

the circuit fluid to a calculated gravimetric level of 10 mg/L using ACFTD.

Circulate the fluid in the element test circuit at a rate equal to the element

flow rate plus or minus 5 percent. Fully open the valve at the upstream and

Circulate the fluid in the test system for 1 hour.

downstream-sample points.

With the automatic-particle counter sensors connected in-line, record cumulative

particle counts at 3 and 5 micrometers every 2 minutes, synchronizing the counting

periods of the two sensors. The validation test shall be accepted only if:

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business