MIL-DTL-24402/5B(SH)

MOUNTING FLANGE CONFIGURATION. The differential pressure indicator mounting flange configuration

shall be designated by a suffix as follows:

No suffix

-

Standard 4-hole flange to mate with figure 1 gland of MIL-DTL-24402.

D

-

Dual-bolt circle, 8-hole flange to mate with figure 1 gland of MIL-DTL-24402 but also

containing four holes of 0.172±0.003-inch diameter equally spaced on a 1.069-inch

diameter bolt circle.

The D suffix is included in the part number to identify an indicator suitable for multiple mounting configurations for

logistic support.

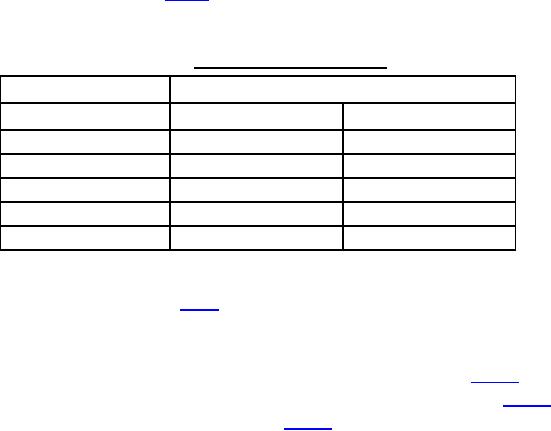

PART NUMBER CROSS REFERENCE. Table I provides a cross reference between old (MIL-F-24402D and

earlier) and new part numbers.

TABLE I. Cross reference of part numbers.

New part numbers

Old part numbers

(Fatigue rated)

(Fatigue rated)

(Non-fatigue rated)

M24402/5-E90

M24402 Form E-3

M24402 Form E-0

M24402/5-E45

-

-

M24402/5-G150

M24402 Form G-3

M24402 Form G-0

M24402/5-M90

M24402 Form M-3

M24402 Form M-0

M24402/5-M45

-

-

SUBSTITUTION OF ASSEMBLIES. Indicators with new part numbers may be substituted for corresponding

indicators with old part numbers as shown in table I. Only indicators with old part numbers that are fatigue rated

may be substituted for indicators with new part numbers.

REQUIREMENTS.

a.

Configuration. The indicators shall comply with the envelope dimensions shown on figure 1.

(1) Male gland dimensions. The male gland shall comply with the dimensions shown on figure 2.

(2) Seals. The O-rings and backup ring specified on figure 2 shall be supplied already assembled onto the

indicator.

(3) Mounting fasteners. The mounting fasteners may be NAS 1351N4H*, where `* is the length of the

fastener in sixteenths of an inch. Length of the fastener shall be selected to provide a thread

engagement of between 1¼ and 1½ times the diameter of the fastener. Fastener torque values shall be

as specified (see 6.2 of MIL-DTL-24402).

b.

Maximum rated operating pressure. The indicators shall have a rated operating pressure of 3,000 lb/in².

c.

Surge lockout pressure. For mechanical and electrical indicators. The minimum surge lockout differential

pressure shall be 15 lb/in² greater than the nominal actuation differential pressure.

2

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business